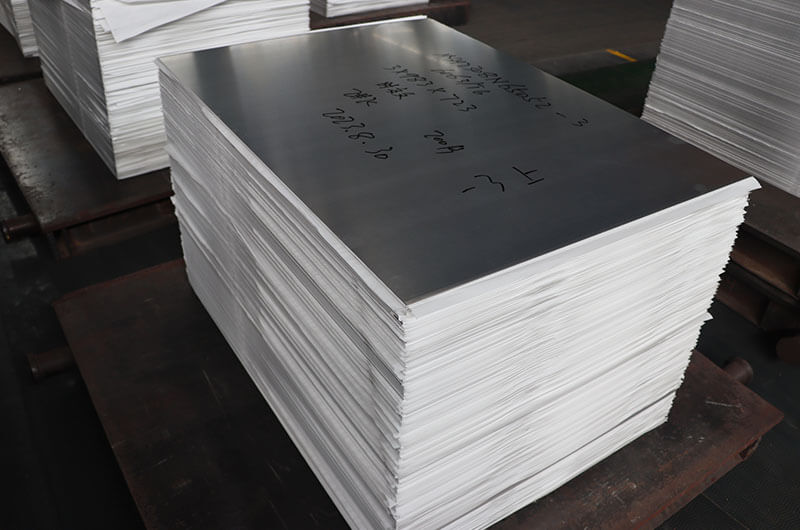

1050-h32 corrosion-resistant aluminum plate

- Alloy: 1050 Aluminum Sheet

- Temper:H32

- Usage:Thin plate processing parts, welded parts, heat exchangers, nameplates, kitchenware, decorations, reflective equipment, etc.

- Thickness:0.1—500mmmm

- Date:2023-11-02

- Consult now

- Henan Mingtai Al.Industrial Co.,Ltd. (Stock Code:601677)

- Address:

No.6 Changchun Rd, High & New Tech Zone, Zhengzhou, Henan, China 450001 - Phone:

0086-17320140933 - Contact: Judy

- WhatsApp:

0086-17320140933 - Email:

Thin plate processing parts, welded parts, heat exchangers, nameplates, kitchenware, decorations, reflective equipment, etc.

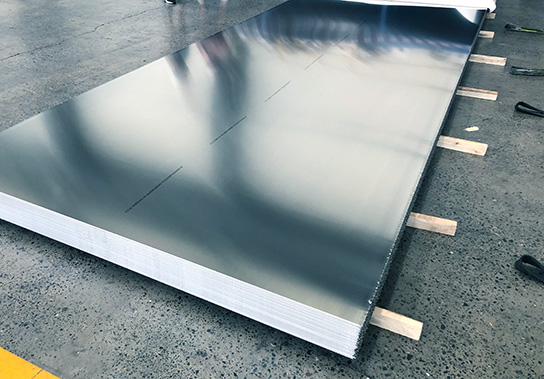

1050 aluminum alloy is a pure aluminum alloy with an aluminum content of more than 99.5%. It has excellent forming and processing properties, good corrosion resistance, good electrical conductivity and welding properties, and can be widely used in: heat exchangers, reflective equipment, Kitchenware, nameplates, welded parts, thin plate processing parts, etc.

1050 aluminum plate product characteristics

1. Hardness characteristics: Uniform hardness, suitable for complex stamping, bending, stretching, and shaping, and not easy to break.

2. Surface treatment characteristics: The material is pure and suitable for high-demand and stable anodizing surface treatment.

3. Mingtai Aluminum has a high level of processing technology, skilled craftsmanship, and stable and reliable product performance;

4. Mingtai has a self-sales model and has a good price advantage.

1050 mechanical properties

Tensile strength σb (MPa)95~125

Conditional yield strengthσ0.2 (MPa)≥75

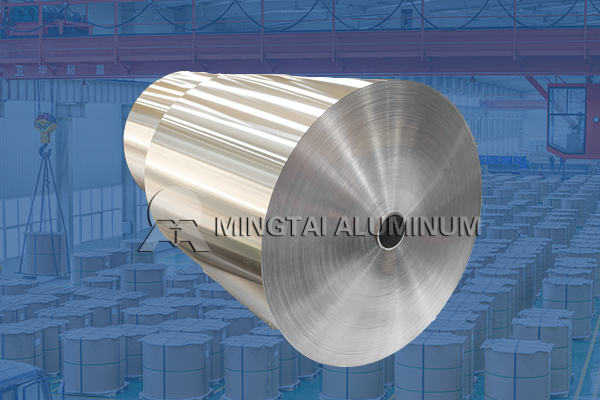

Mingtai Aluminum 1050-h32 aluminum plate manufacturer

Henan Mingtai Aluminum is a professional large-scale 1050-h32 aluminum plate manufacturer with strong production strength. It has semi-continuous casting production lines, continuous casting and rolling production lines, cold rolling mills, foil rolling mills, bending and straightening cleaning machines, and flying shear machines. , slitting machines, slitting and other large-scale processing equipment. The annual output can reach 1.2 million tons. The product quality is guaranteed. All products are direct ex-factory prices, fast delivery, low prices, and complete after-sales service. Obtain For quotation points, you can call: 135-9245-5601. The professional business manager will give you detailed answers!