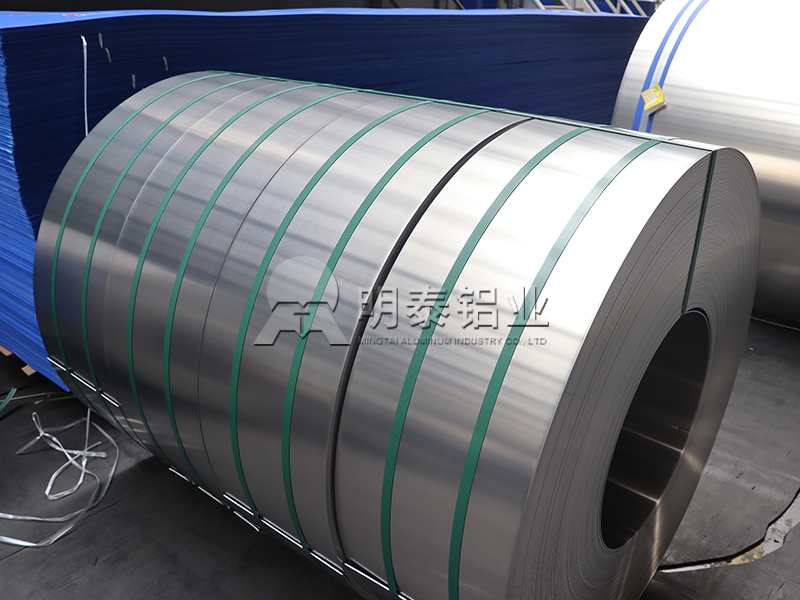

1060 aluminum coil

- Alloy: 1060

- Temper:H24

- Usage:Thermal insulation

- Thickness:0.3-1.0mmmm

- Date:2022-10-28

- Consult now

- Henan Mingtai Al.Industrial Co.,Ltd. (Stock Code:601677)

- Address:

No.6 Changchun Rd, High & New Tech Zone, Zhengzhou, Henan, China 450001 - Phone:

0086-17320140933 - Contact: Judy

- WhatsApp:

0086-17320140933 - Email:

1060 aluminum coil is one of the commonly used thermal insulation materials

Pipeline insulation layer, also known as thermal pipeline insulation layer, refers to the layered structure wrapped around the pipeline for thermal insulation. The pipe insulation layer is usually composed of three layers: insulation layer, protective layer and waterproof layer. 1060 aluminum coil is one of the commonly used thermal insulation materials, which is mainly used for rust prevention and thermal insulation works of pipelines, equipment, plants, buildings and other facilities.

1060 thermal insulation aluminum coil has good advantages

1. As the proportion of aluminum is 2.71, the weight of aluminum sheet per square meter is very light, which can save a lot of raw materials for enterprises and reduce costs.

2. As aluminum has the characteristics of aluminum, its exterior is bright and clean, so there is no need to worry about rust stains on the product in the later stage.

3. It is convenient for construction. Aluminum has high plasticity and can be easily bent and wound. It greatly improves the working efficiency.

4. The service life of thermal insulation aluminum coil is long.

Alloy composition of 1060 aluminum coil

Aluminum Al (%)99.60

Silicon Si (%)0.25

Copper Cu (%)0.05

Mg (%)0.03

Zinc (%)0.05

Manganese Mn (%)0.03

Titanium Ti (%)0.03

Vanadium V (%)0.05

Iron Fe (%)0.350

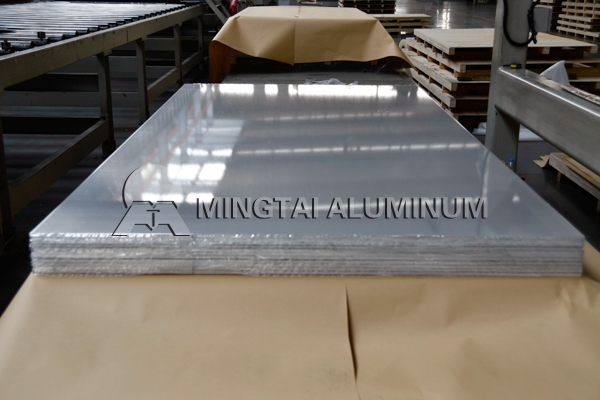

Mingtai Aluminum supplies 1060 aluminum coils

Mingtai Aluminum supplies 1060 aluminum coils, which can be customized. The products are commonly used in signboards, billboards, building exterior decoration, fan blades, electronic parts, chemical instruments, sheet processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surfaces and plates, nameplates, kitchenware, decorations, reflective appliances, etc.

Mingtai has five production bases, with a total production base area of more than 1.3 million square meters, an annual production capacity of 1.4 million tons, and a short delivery time to meet your production needs.