1100 aluminum sheet for aluminum composite panel

- Alloy: 1100 alloy

- Temper:H18

- Usage:ACP

- Thickness:0.2-0.4mmmm

- Date:2022-11-09

- Consult now

- Henan Mingtai Al.Industrial Co.,Ltd. (Stock Code:601677)

- Address:

No.6 Changchun Rd, High & New Tech Zone, Zhengzhou, Henan, China 450001 - Phone:

0086-17320140933 - Contact: Judy

- WhatsApp:

0086-17320140933 - Email:

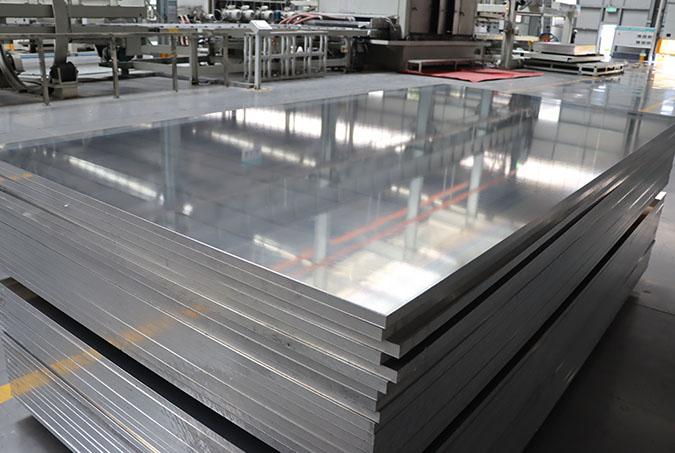

Aluminum composite panel

Aluminum composite panel generally adopts 4-6mm multi-layer composite structure, with 0.5mm thick high-purity Aluminum sheets at the top and bottom, PE or PVC interlayer in the middle, and a protective film pasted on the front. Aluminum composite panel is a new type of building material, which is widely used in exterior wall decoration, signboards, exhibition boards, advertising billboards, building partitions and interior wall decorative panels.

Aluminum composite panel will use 1100 Aluminum sheet

The upper and lower aluminum composite panels generally use 1100 aluminum sheet, 3003 aluminum sheet, etc. The 1100 aluminum sheets/strips produced by Mingtai Aluminum are used for the processing and manufacturing of aluminum composite panels. They are usually H16, H18, etc., and have multiple advantages such as good shape, flat and clean surface.

Performance advantages of 1100 aluminum sheet

1. High plasticity, corrosion resistance, conductivity and thermal conductivity

2. Gas welding, hydrogen atom welding and contact welding

3. Easy to bear various pressure processing, extension and bending

4. It is impact resistant, can reduce building load, and has good shockproof performance

5. Good flatness, light and hard

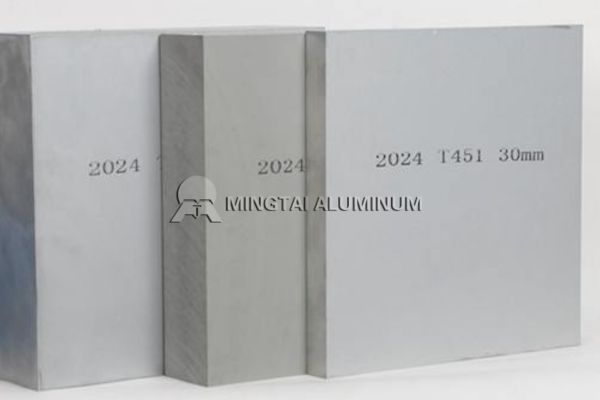

1100 aluminum sheet manufacturer

Henan Mingtai Aluminum 1-8 series aluminum sheet, strip and foil manufacturer. Listed companies have complete product models and specifications, which can be customized as needed, with guaranteed quality, stable and reliable performance, and affordable prices. Please continue to visit this website for more product details.