2A11 Aluminum plate

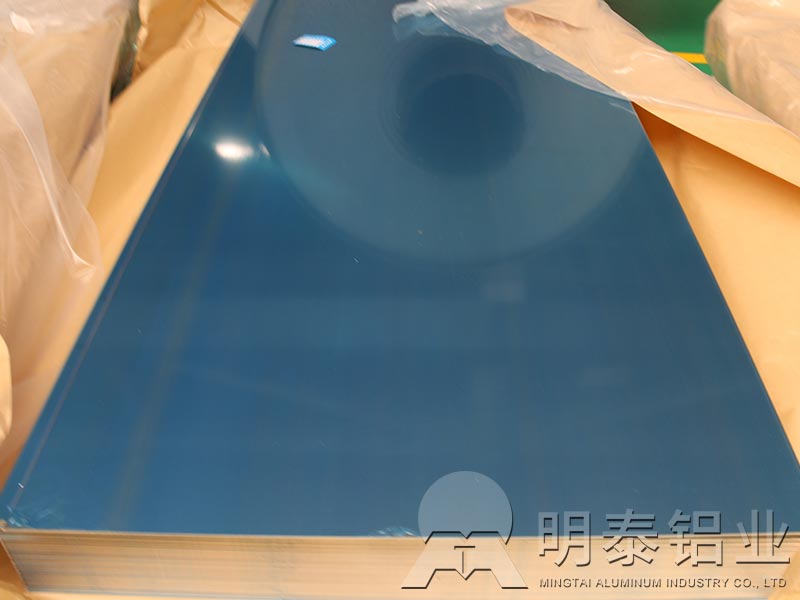

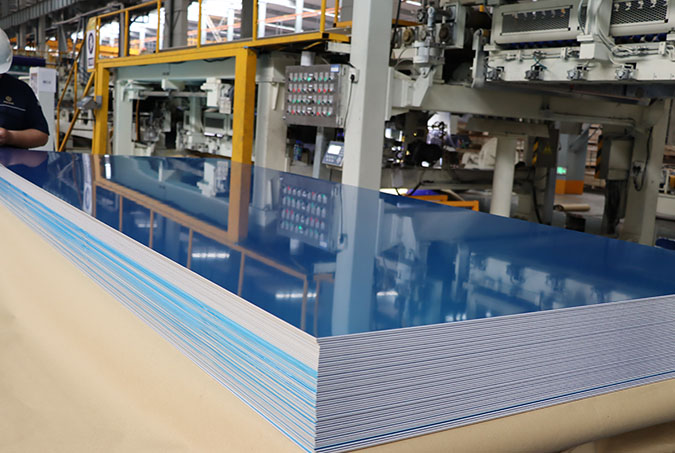

- Alloy: 2A11 Aluminum Plate

- Temper:T4, T6, T351, H112

- Usage:Molds, high-strength components, rivets, etc

- Thickness:8.0-90mm

- Date:2024-04-07

- Consult now

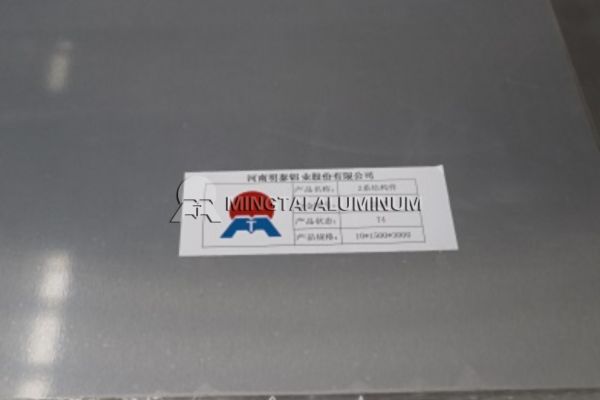

- Henan Mingtai Al.Industrial Co.,Ltd. (Stock Code:601677)

- Address:

No.6 Changchun Rd, High & New Tech Zone, Zhengzhou, Henan, China 450001 - Phone:

0086-17320140933 - Contact: Judy

- WhatsApp:

0086-17320140933 - Email:

2A11 aluminum alloy is a high-strength hard aluminum that has good plasticity in annealing, quenching, and hot states. It can be strengthened by heat treatment and can be used in quenching and natural aging states. It has good spot welding performance and tends to crack when using 2A11 as a welding material for gas welding and argon arc welding; Aluminum coated panels have good stability, while those without aluminum coating have low corrosion resistance. When heated above 100 ℃, there is a tendency for intergranular corrosion

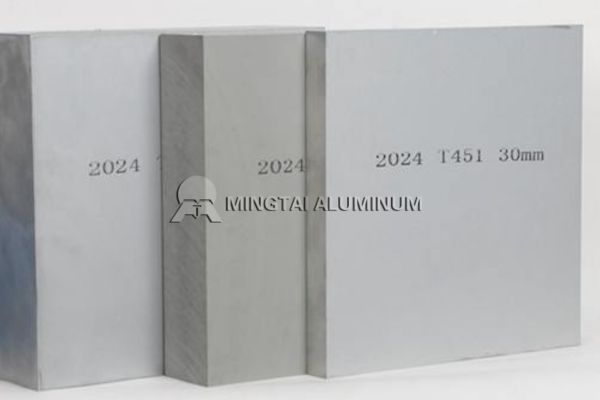

Technical parameters of 2A11 aluminum plate

Typical alloys:2A11 aluminum plate

Material status:T4, T6, T351, H112

Thickness (mm):8.0-90

Width (mm):500-2650

Length (mm):500-16000

Typical products:Molds, high-strength components, rivets, etc

2A11 Aluminum Plate Market Application

Rivet industry radiators, mold manufacturing, shipbuilding, heavy forgings, thick plates and extruded materials, truck components, automotive car covers, automotive accessories and other fields.

Chemical composition of 2A11 aluminum plate:

Silicon Si: 0.7

Iron Fe: 0.7

Copper Cu: 3.8-4.8

Manganese Mn: 0.40-0.8

Magnesium Mg: 0.40-0.8

Zinc Zn: 0.30

Titanium Ti: 0.15

Nickel NI: 0.1

Iron+nickel Fe+Ni: 0.50

Aluminum Al: Surplus

Other:

Single: 0.05; Total: 0.10