3003 aluminum sheet for power battery shell-Mingtai Aluminum Industry

- Alloy: 3003

- Temper:H14

- Usage:Power battery shell

- Thickness:0.6-2.5mmmm

- Date:2022-06-27

- Consult now

- Henan Mingtai Al.Industrial Co.,Ltd. (Stock Code:601677)

- Address:

No.6 Changchun Rd, High & New Tech Zone, Zhengzhou, Henan, China 450001 - Phone:

0086-17320140933 - Contact: Judy

- WhatsApp:

0086-17320140933 - Email:

3003 aluminum sheet for power battery case

The battery is one of the core components of the new energy electric vehicle. Its packaging process is very important in the production process of power batteries. Good packaging determines the safety and life of the battery. Therefore, choose a high-quality aluminum power battery shell material, and choose the optimal packaging process according to the characteristics of the shell material. It is especially important for the safety and service life of the battery. At present, 3003 aluminum sheet is generally used for electric vehicle aluminum power battery shell.

Properties of 3003 aluminum sheet for power battery case

This material is easy to form, high temperature corrosion resistance, good heat transfer and electrical conductivity. The aluminum power battery shell (except the shell cover) of 3003 aluminum alloy can be drawn and formed at one time. Compared with the stainless steel shell, the welding process of the bottom of the box can be omitted.

3003 is mainly aluminum-manganese alloy, and the main alloying element is manganese. The boiling point temperature of aluminum and manganese is not much different, and there will be no problems such as the deterioration of weld quality due to the burning of metal elements during welding.

Advantages of 3003 aluminum sheet for power battery case

1. Explosion-proof performance

2. Anti-aging properties

3. Long service life

4. Flame retardant, smokeless, nontoxic

In order to increase the cruising range, new energy electric vehicles need a large number of lithium battery combination modules. Each module is composed of several battery boxes. In this way, the quality of each battery box has a great impact on the quality of the entire battery module. In order to reduce the quality of the battery, it is an inevitable choice to use 3003 aluminum alloy material to make the battery case.

The advantages of 3003 aluminum alloy

The 3003 aluminum alloy material has the advantages of low density and soft material, and has the advantages of easy overall drawing and forming of the aluminum shell of the power battery, and has been used by many enterprises for battery packaging. Aluminum alloys are much less dense than traditional stainless steel encapsulation materials.

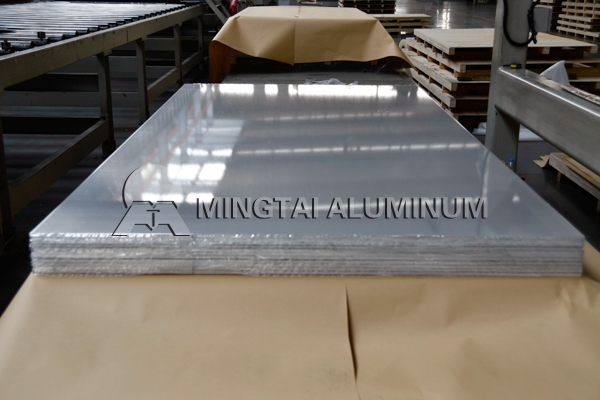

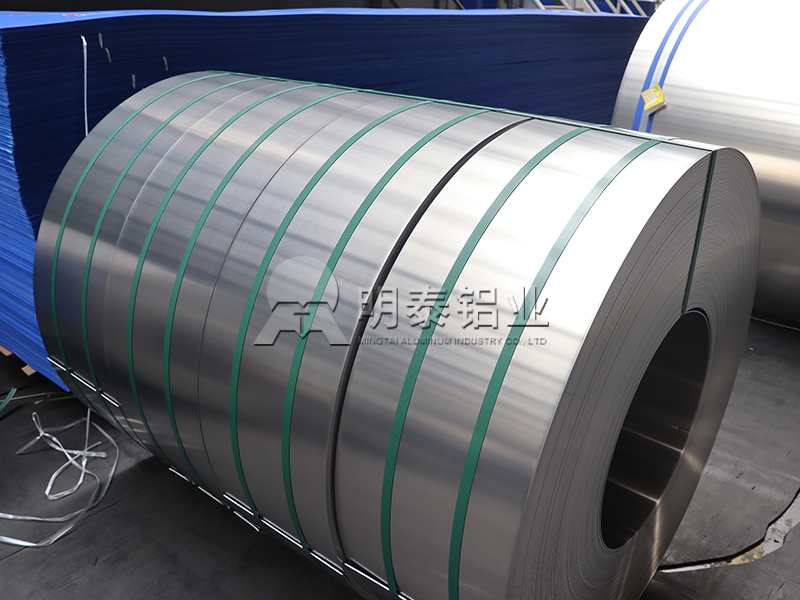

Mingtai Aluminum produces power battery shell material 3003 aluminum material

Mingtai Aluminum produces power battery shell material 3003 aluminum plate, which is customized according to customer requirements. As a large-scale aluminum plate, strip and foil processing enterprise in China, Mingtai Aluminum has invested heavily in the research and development of aluminum power battery shells. The products produced are of high quality and exported to overseas.