5A05 aluminum plate technical parameters

- Alloy: 5A05

- Temper:

- Usage:

- Thickness:mm

- Date:2023-12-28

- Consult now

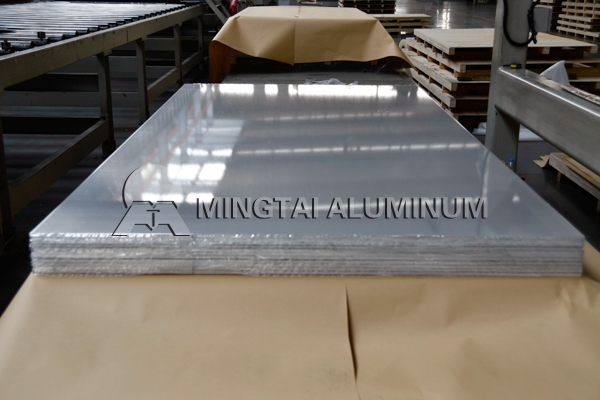

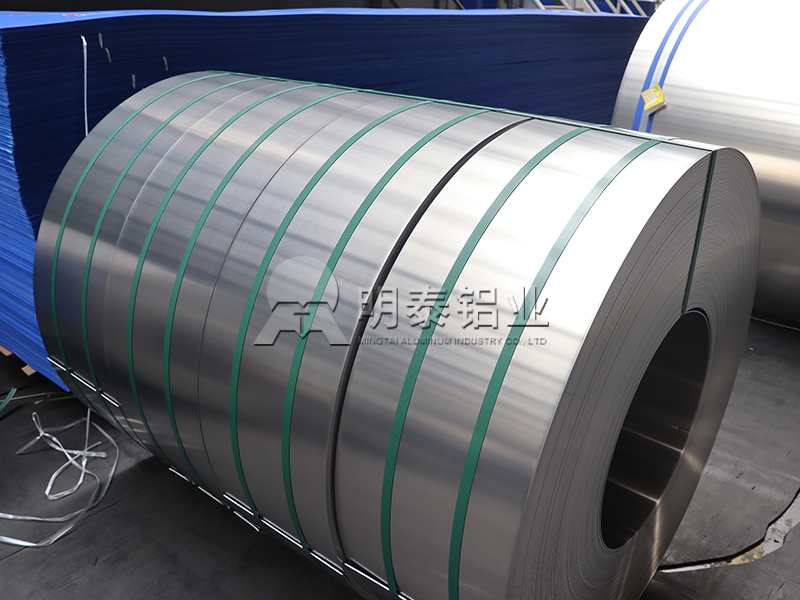

- Henan Mingtai Al.Industrial Co.,Ltd. (Stock Code:601677)

- Address:

No.6 Changchun Rd, High & New Tech Zone, Zhengzhou, Henan, China 450001 - Phone:

0086-17320140933 - Contact: Judy

- WhatsApp:

0086-17320140933 - Email:

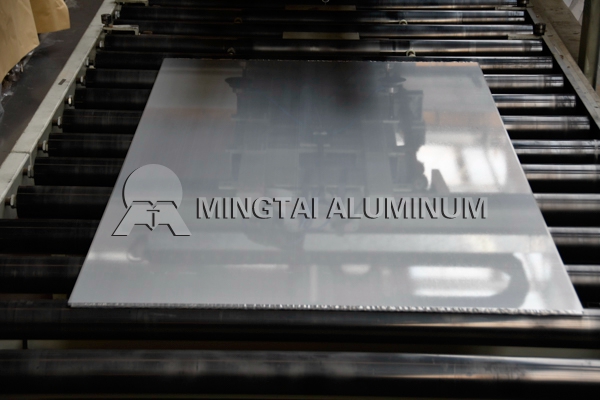

5A05 aluminum plate is an Al-Mg rust-proof aluminum alloy and cannot be strengthened by heat treatment. This alloy has a higher magnesium content and its strength is lower, similar to that of 5A03 alloy. Cold deformation of alloys can increase strength but reduce plasticity. The plasticity in the annealed state is high, and the plasticity in the semi-cold work hardening state is acceptable. The alloy has good corrosion resistance and acceptable weldability, and is suitable for spot welding, atomic hydrogen welding, gas welding, and argon arc welding. Its machinability is very poor in the annealed state, but is good in the semi-cold work hardening state.

5A05 aluminum plate technical parameters

Typical Alloy Material Condition Thickness (mm) Width (mm) Length (mm) Typical Products

5A05 aluminum plate

F,O,H12,H14,

H16,H18,H19,

H22,H24,H26,

H28,H32,H34

H36,H38,H111,

H112,H114,H116,H321

1-500 100-2650 500-16000 Ship and transportation vehicle sheet metal parts, fuel tanks, flanges, etc.

5A05 aluminum alloy is usually used to manufacture welded pipes, welded mailboxes and other liquid containers, and other parts that require high process plasticity, good corrosion resistance, and medium load resistance; wire rods are used as welding rods and rivets, and the rivets require anodizing. Abroad, similar alloys (such as 5454 aluminum plates) are used to make armor plates and high-strength structural parts. Storage tanks, pressure vessels and marine supplies, etc.