-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

Cosmetic bottle cap material 1070 aluminum plate

The bottle cap, as the sealing component of the bottle, is an important part of container packaging. The basic function of bottle caps is sealing, which provides protection for the contents. The sealing performance of bottle caps directly determines the packaging quality of packaging products. In the field of cosmetic packaging, bottle caps also play an important role - aesthetics. A well-designed aluminum cap can enhance the quality of cosmetics.

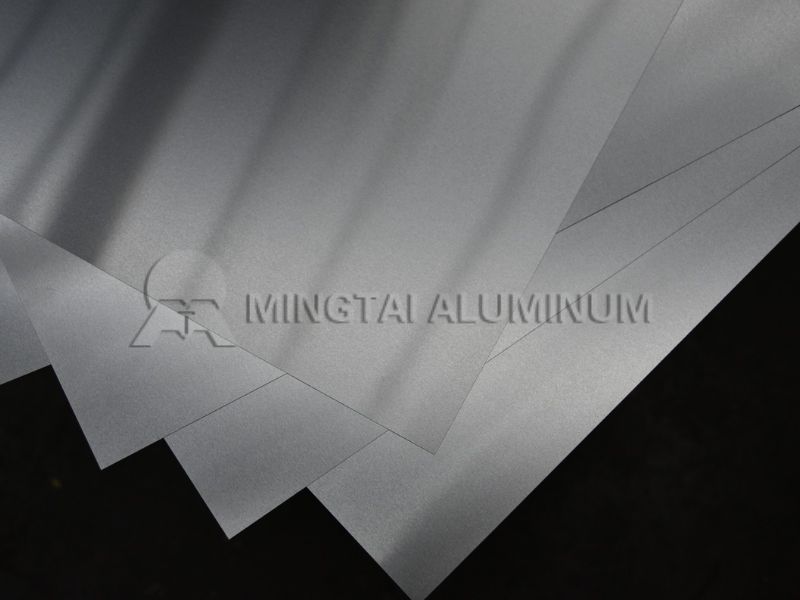

At present, the competition in the domestic cosmetics industry is fierce, and companies attach great importance to the design of outer packaging while focusing on product quality. The emergence of various packaging forms better meets the personalized needs of products. Aluminum alloy is the raw material for manufacturing high-end cosmetic bottle caps, usually made of 1070 aluminum plate, belonging to the pure aluminum series. It has good oxidation effect, bright surface, and excellent stamping formability, and has been adopted by many enterprises.

In the field of cosmetics, aluminum caps are widely used. Compared to bottle caps made of other materials, aluminum caps have the following advantages:

1. Good sealing performance

Sealing is a fundamental and critical function in packaging products, and aluminum caps have strong sealing properties, making them widely used.

2. Beautiful appearance

The aluminum alloy material used for cosmetic bottle caps can achieve a mirror like effect after stamping, stretching, mechanical polishing, electrolytic polishing, and anodizing coloring. It has rich color, strong metallic feel, and stain resistance, and is popular in the market.