-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

5083 aluminum plate ultra wide size for speedboat

In the field of shipbuilding, the selection of materials is directly related to the durability, safety, and overall performance of ships. With the rapid development of materials science, the selection of marine materials is becoming increasingly diversified. 5083 aluminum plate, as a high-performance aluminum alloy material, has become the preferred material for ship construction, deck laying, and offshore platform structures due to its excellent corrosion resistance, good weldability, and high strength.

Introduction to the Performance of 5083 Aluminum Plate for speedboat

5083 aluminum plate is a high-strength aluminum alloy material, whose main alloying elements include magnesium and a small amount of manganese, chromium, etc. The addition of these elements makes 5083 aluminum plate have excellent corrosion resistance, good weldability and formability, as well as high fatigue strength and impact resistance. These characteristics make 5083 aluminum plate an indispensable key material in shipbuilding, widely used in multiple key parts such as ship structures, decks, bulkheads, fuel tanks, pipeline systems, etc.

Excellent corrosion resistance: The complex and ever-changing marine environment, high salinity, high humidity, and the presence of microorganisms pose severe challenges to materials. 5083 aluminum plate effectively resists seawater corrosion and extends the service life of ships through alloying design and surface treatment technology.

Good weldability and formability: Welding and forming of materials are critical processes in shipbuilding. 5083 aluminum plate is easy to weld and can maintain high strength after welding. At the same time, its good formability also meets the design requirements of complex ship structures.

High strength and lightweight: While ensuring strength, 5083 aluminum plate has a lower density compared to traditional steel, which helps achieve lightweight design of ships, improve navigation speed and fuel efficiency.

5083 aluminum Plate Specifications

The commonly used specification for 5083 aluminum plate is 1220 * 2440mm

The thickness of 5083 marine aluminum alloy sheet is determined by the structure of the ship, the specifications of the ship, and the location of use. From the perspective of lightweighting of the ship, thin plates are generally used as much as possible, but the depth of corrosion of the sheet during use should also be considered. The commonly used marine aluminum sheet includes thin plates of 1.6mm or more and thick plates of 30mm or more. To prevent slipping, the deck is made of patterned boards.

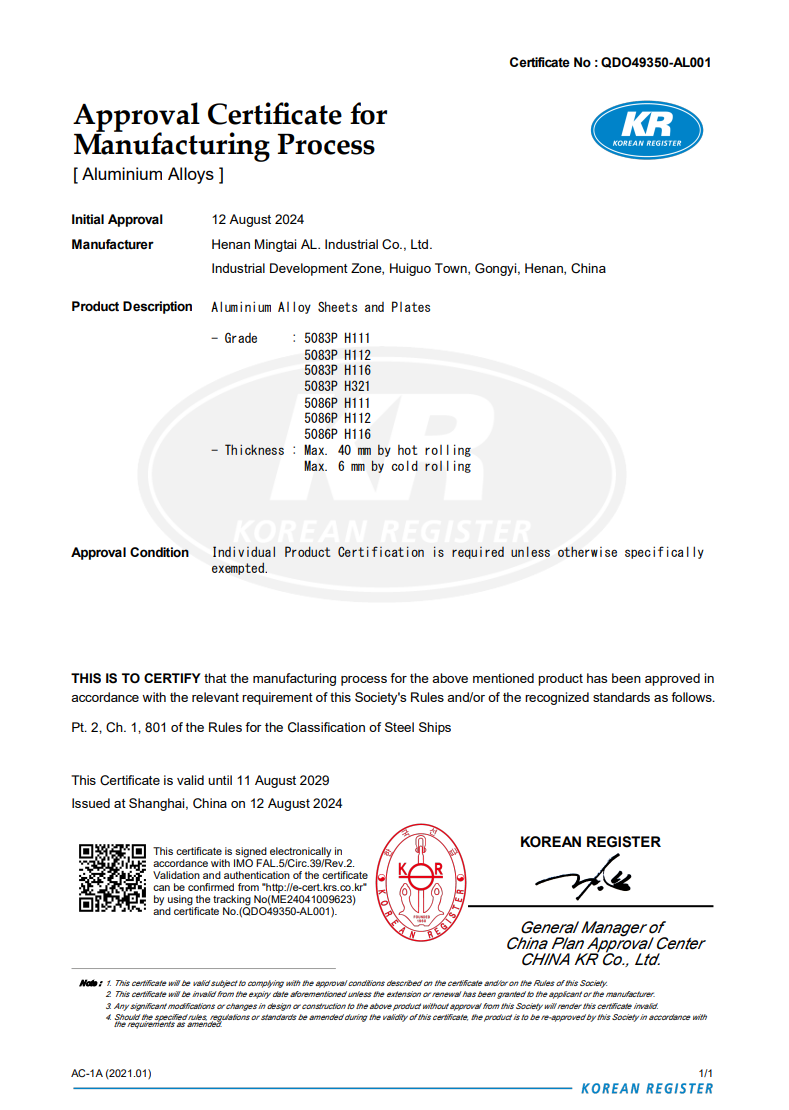

5083 aluminum Plate Certification

Mingtai Aluminum's 5083 aluminum plate has been certified by China Classification Society and Korea Classification Society, with high toughness, corrosion resistance, and weldability. The quality of 5083 marine aluminum plate is guaranteed. For related needs, please feel free to consult.