-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

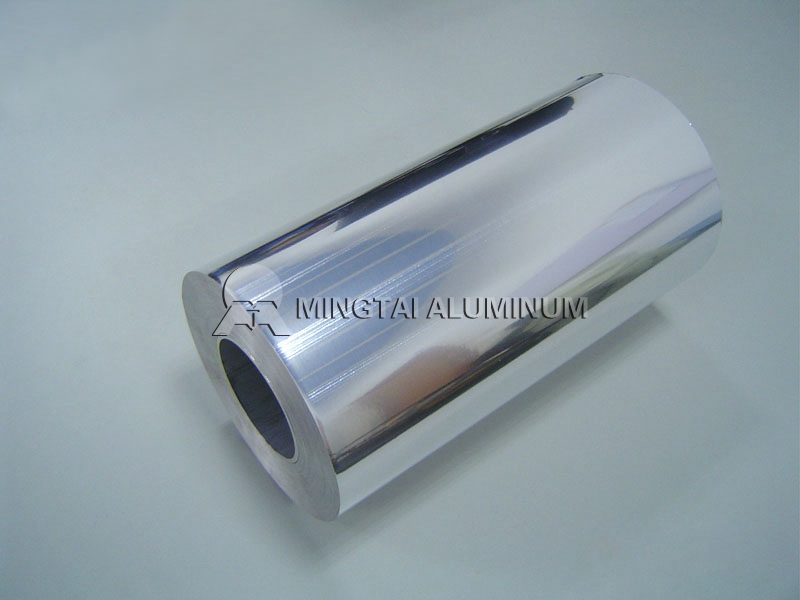

High Quality 1235 8011 Aluminum foil jumbo roll for cable tape

Aluminum foil has always been used as an insulation material for cables. Its sealing and shielding properties mainly serve as a protective cover for cables. Commonly used aluminum foil alloys for cables include 1235, 8011, 1100, 1050 and 1060 aluminum alloys, which are lightweight, flexible, suitable for various wires and cables, and have good corrosion resistance.

High quality Aluminum foil for cable tape

Typical alloys: 1235, 1060, 1050, 1100, 8011

Material status: O, H22, H24

Thickness: 0.016-0.55mm

Width: 100-1600mm

Length: C

Advantages of using 1235 8011 aluminum foil for cable tape

Aluminum has a relatively low density, light weight, excellent oxidation resistance and corrosion resistance, is not easily corroded, and has a long storage time.

Aluminum has good ductility and is easy to seal. Aluminum alloy has excellent bending performance, and its unique alloy formula and processing technology greatly improve flexibility.

Excellent insulation performance, aluminum strip has the characteristic of excellent insulation performance, which can effectively prevent electromagnetic wave interference in cable lines and improve the transmission efficiency of cable lines.

1235 Aluminum foil for cable shielding and 8011 aluminum foil for cable tape can reduce cable weight and have a high recycling rate, reducing installation costs.