-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

3003 ultra wide aluminum plate for silo

Aluminum has excellent physical and mechanical properties, with low density, high strength, high thermal conductivity, high electrical conductivity, and strong corrosion resistance. Aluminum alloy materials are increasingly being used in petrochemical plants, gradually becoming the main material for silos and containers, and widely used in welded structures such as containers, machinery, electricity, and chemical products.

The storage bin is the main large-scale equipment in the pneumatic conveying device of the bin, which measures and stores the materials purchased by enterprises after pneumatic conveying and unloading. The structural type of large silos is vertical cylindrical, with two types of tops: flat top and conical top, and two types of bottoms: single cone and double cone. Aluminum alloy material is one of the commonly used materials in the production of silos.

The 3003 aluminum alloy silo has strong corrosion resistance and is not corroded by residual chlorine in external air and water. The 3003 aluminum alloy silo requires strong pressure resistance, and the 3003 deep drawn aluminum plate meets the requirements. The silo is made of 3003 aluminum plate, which has moderate strength, good plasticity and corrosion resistance, hence it is called anti rust aluminum plate and has good weldability.

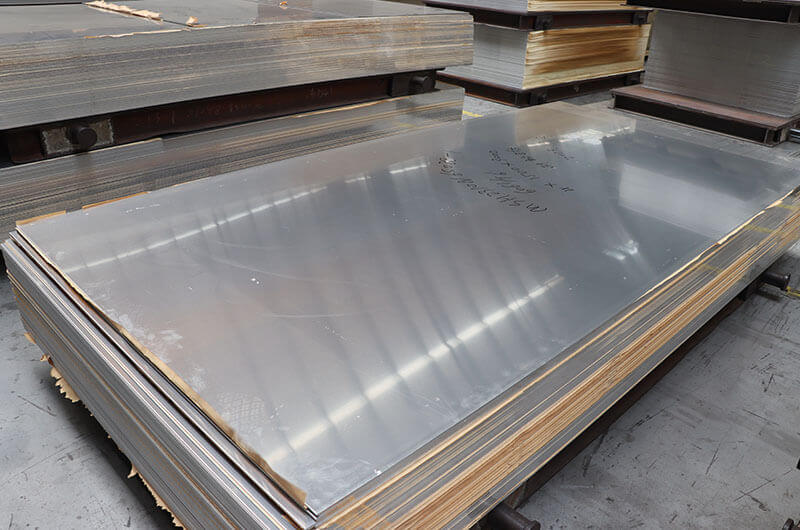

Mingtai Aluminum Industry supplies 3003 aluminum alloy warehouse materials and aluminum substrates. Mingtai Aluminum Industry produces 3003 deep drawn aluminum plates with good formability, deep drawing performance, smooth surface, good plasticity, and strong pressure resistance; 3003 aluminum plate forming processing characteristics, high corrosion resistance, and good weldability. Mingtai Aluminum produces 3003 aluminum plates with a width of up to 2650mm.

Please feel free to consult online:

Email Us:sale06@mingtai-al.com

wa.me/+8617320140933