1060 Aluminum Sheet for Conductive-Aluminum Busbar Base Material

- Alloy: 1060 Aluminum Sheet

- Temper:H112

- Usage:Aluminum busbar, conductive aluminum

- Thickness:10-300mmmm

- Date:2022-07-20

- Consult now

- Henan Mingtai Al.Industrial Co.,Ltd. (Stock Code:601677)

- Address:

No.6 Changchun Rd, High & New Tech Zone, Zhengzhou, Henan, China 450001 - Phone:

0086-17320140933 - Contact: Judy

- WhatsApp:

0086-17320140933 - Email:

1060 aluminum sheet for conduction

Busbar refers to a product made of high-conductivity copper (copper bar) and aluminum materials to transmit electrical energy, collect and distribute electrical power. The main conductor used to transmit electrical energy in a power station or substation. Through it, the electrical energy output by the generator, transformer or rectifier is delivered to various users or other substations. 1050 aluminum sheet, 1060 aluminum sheet, 1070 aluminum sheet for busbar, H112 temper

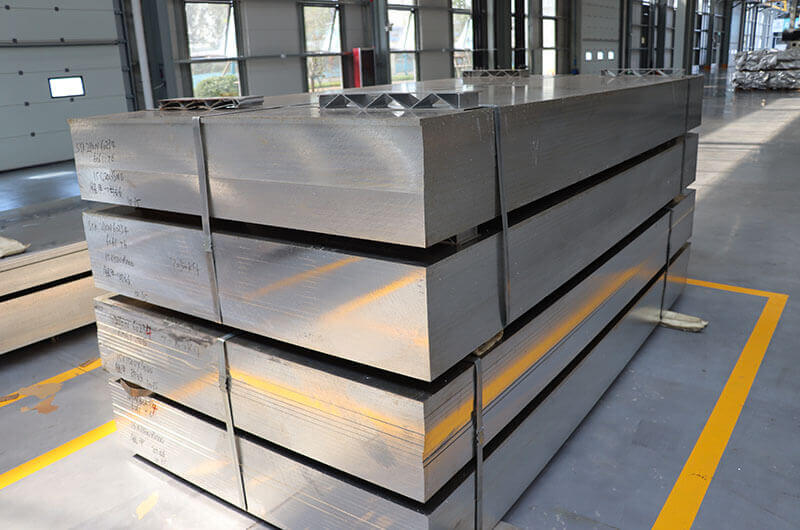

1060 aluminum sheet thickness

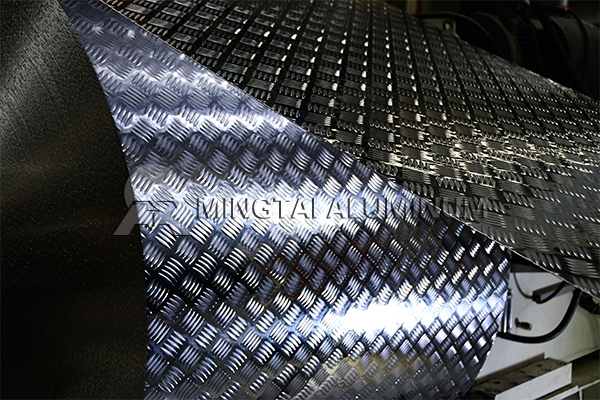

The closed busway (referred to as the busway) is a busbar system composed of a metal plate (steel plate or aluminum sheet) as a protective shell, conductive bars, insulating materials and related accessories.

The main features of aluminum sheet for aluminum alloy busway are corrosion resistance, light weight and high strength. Aluminum alloy bus ducts are mostly produced by pure aluminum sheets. The main alloy grades are 1060 aluminum sheets and 1070 aluminum sheets, and the common thickness ranges from 10-400mm.

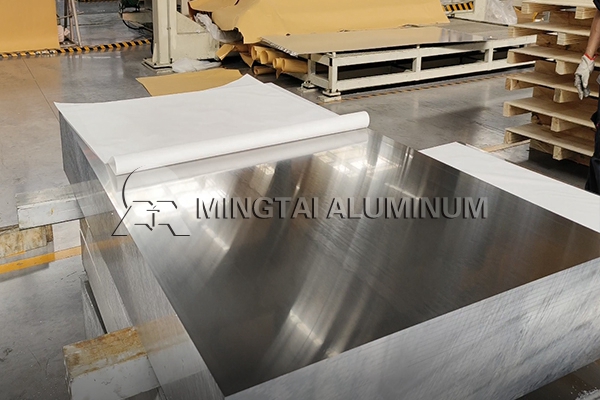

1060 aluminum sheet manufacturer Mingtai Aluminum

Mingtai Aluminum Co., Ltd. is a large-scale aluminum busway aluminum sheet raw material manufacturer. The 1060/1070 aluminum busway aluminum sheet produced has high strength and flat plate shape. It cooperates with many aluminum busbar manufacturers and has successfully exported to more than 40 countries and regions.

Advantages of aluminum sheet for aluminum alloy busbar

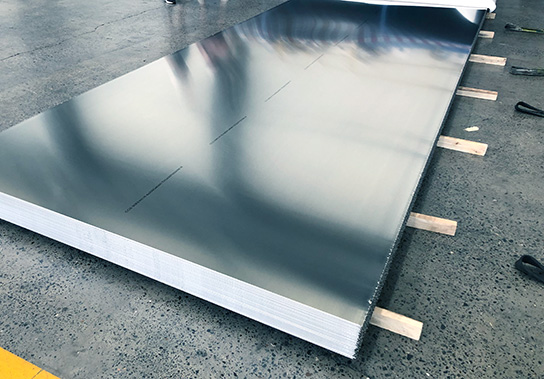

1. The flatness of the board surface is high and the shape of the board is good

Equipped with a shape controller to monitor the shape in real time; follow-up drawing and straightening process, secondary correction of the shape; to ensure that the aluminum foil has a good shape, high layout flatness, and good shape accuracy!

2. High strength, not easy to deform after processing

Using 1070 aluminum sheet and 1060 aluminum sheet as the base material of aluminum busway aluminum sheet, the strength is high, and the finished product is not easy to deform

3, anti-corrosion and corrosion resistance, good conductive effect

1060/1070 aluminum bus duct is made of pure aluminum sheet, which has good electrical conductivity and excellent anti-corrosion performance after anodic oxidation.