-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

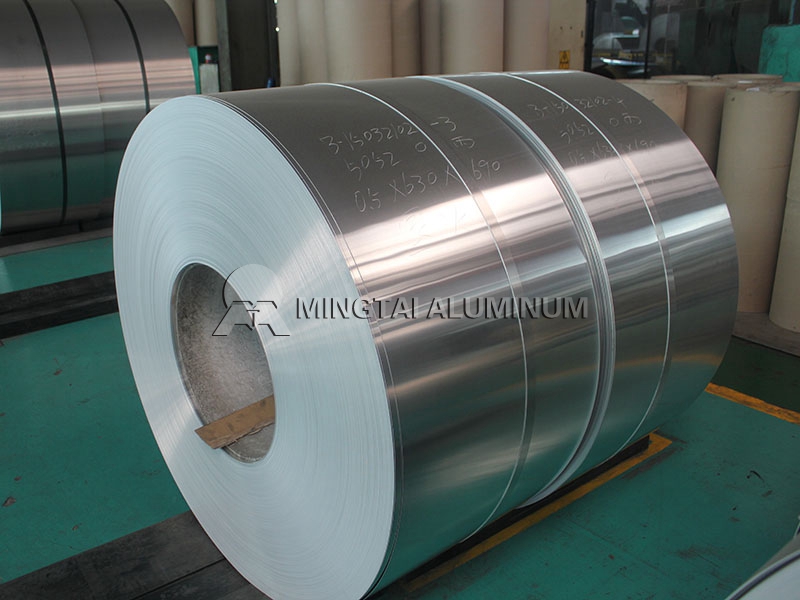

1100 h14 Mill Finish Aluminum Coil for ACP

Aluminum Composite Panel usually use 1100 aluminum coils as one of the materials, which have good ductility, formability, and corrosion resistance, and are suitable for manufacturing building decoration materials such as aluminum-plastic panels. In addition, 1100 aluminum coils are widely used in curtain wall decoration, especially in situations where excellent molding production and processing performance and high corrosion resistance are required. The building exterior wall made of aluminum-plastic panel rolls has the advantages of corrosion resistance, light weight, easy installation, sound insulation, and economic and environmental protection

Characteristics of 1100 aluminum coil

High aluminum content, high mechanical strength

Excellent ductility, processability, and corrosion resistance

- Widely used in large refrigerators, HVAC systems, building decorations, etc

- Used for ACP polishing, deep stamping parts, sheet metal processing parts

- Tensile strength :150MPa

- Annealing process: H24, H18, H14

1100 Aluminum Coil Product Specification

Thickness range: 0.02mm -12.00mm

Length: 20mm -8000mm

Annealing process and performance

H24 Annealing Process: Semi hard state, suitable for conventional use

H14 annealing process: medium configuration, suitable for curtain walls and aluminum veneers

1100 Aluminum coil VS 1060 Aluminum coil

1100 aluminum coil has higher tensile strength

Suitable for occasions that require good plasticity and corrosion resistance

Production and customization services

Mingtai Aluminum provides customized services,mainly engaged in various aluminum coil products

Email Us:sale06@mingtai-al.com

wa.me/+8617320140933