-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

8011 Alloy grade of Aluminium foil for ROPP Caps

The most common alloy for closures is 8011 alloy, which has good formability, good earring rate and flatness, so as to make sure the long cap deep drawing. It often used as ROPP caps for wine bottles, and other beverage bottles.

Compared to plastic bottle caps, aluminum bottle caps have the advantages of simple appearance, fine production, no pollution, and recyclability, and the production cost is only about half of plastic bottle caps. At present, aluminum bottle cap materials on the market are mostly made of 8011 aluminum foil, which requires a flat surface, no rolling marks, scratches, and stains. The commonly used alloy materials include 8001-h14, 8011-h16, 3003-h16, etc. The material specifications are generally 0.20-43.23mm thick, with a tolerance of ± 0.1%, and a width of 449-796mm.

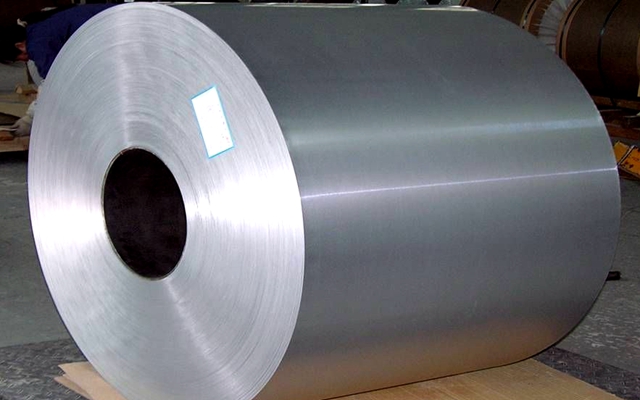

Ropp cap material 8011 aluminum foil

The aluminum bottle cap material produced by Mingtai Aluminum Industry uses 8011 aluminum foil, which enjoys a good reputation and good reputation in both domestic and international markets, due to Mingtai Aluminum Industry's strict control over product quality.

Henan Mingtai has introduced Korean imported flying shears and domestically advanced flat shears, and strictly controls the processing technology of the products. The aluminum substrate used in the production of bottle caps has a tensile strength of 120-140MPa, a yield strength of 120-135MPa, an ear making rate of 0-2%, a thickness difference of+/-0.005, and clean oil removal, with a surface dynein value greater than 56. Advanced equipment and processing technology, as well as a strict quality control system, have made Mingtai Aluminum's aluminum base material for aluminum bottle caps a stable supplier for large-scale bottle cap production enterprises, and exported to more than 40 countries and regions such as India, Australia, and the United States.