-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

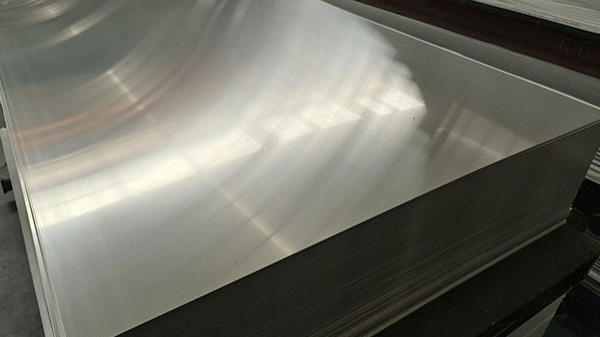

Anti-Rusting 5052 Aluminum Plate for Automobile Fuel Tank

Automobile fuel tanks are usually made of aluminum alloy materials, especially 5052 aluminum plates, which are widely used in the manufacturing of automobile fuel tanks due to their various advantages.

Material selection and advantages:

5052 aluminum plate: 5052 aluminum plate is an aluminum magnesium alloy with high strength, good plasticity, and corrosion resistance. It is one of the main materials for manufacturing automotive fuel tanks. It is not only lightweight and can effectively reduce the total weight of the car, but also less prone to cracking in the event of a severe collision, improving the safety of the vehicle. In addition, 5052 aluminum plate also has good weldability and processability, suitable for stamping and forming.

Other aluminum alloy materials: In addition to 5052 aluminum plate, aluminum alloy plates such as 5083, 5A05 aluminum plate, 5A02, etc. are also used in the manufacturing of automotive fuel tanks. These materials also possess high strength, corrosion resistance, and oxidation resistance, making them suitable for different types of fuel tank requirements.

Market Applications and Trends:

With the development of lightweight automobiles, aluminum alloy fuel tanks have gradually replaced traditional iron fuel tanks. Aluminum alloy fuel tanks not only reduce vehicle weight, but also improve the reliability of the fuel system, reducing fuel pollution caused by rusting of iron fuel tanks.

At present, aluminum alloy fuel tanks have been widely used in large vehicles such as heavy trucks, light trucks, and buses, and occupy a dominant position in the market.

Technology and Process:

Manufacturing aluminum alloy fuel tanks requires a complex process, including batching, melting, refining, casting, sawing, milling, hot rolling, cold rolling, and other steps. These processes ensure stable mechanical properties, precise dimensional tolerances, and good surface smoothness of aluminum alloy sheets.

The application of new technologies, such as aluminum alloy fuel tank partition fixing technology, further improves the service life and safety of the fuel tank.

Environmental Protection and Economic Benefits:

Aluminum alloy fuel tanks have better corrosion resistance and service life compared to iron fuel tanks, reducing maintenance costs and replacement frequency. At the same time, the recycling rate of aluminum alloy materials is high, which meets environmental protection requirements.

The use of aluminum alloy fuel tanks can reduce fuel consumption and emissions, and help improve the environment.

Aluminum alloy materials are widely used in car fuel tanks, especially 5052 aluminum plates, which have become an important choice in the modern automotive industry due to their advantages of lightweight, high strength, and corrosion resistance. With the advancement of technology and the growth of market demand, the application prospects of aluminum alloy fuel tanks will be even broader.

More information:

Email Us:sale06@mingtai-al.com

wa.me/+8617320140933