-

Location:

Mingtai Aluminum Stock Shop >>

News>>

Products Information>>

Performance parameters of 5182-H19 aluminum plate for pull ring

Aluminum alloy cans have the characteristics of light weight, heat resistance, odorless and non-toxic, good printing effect, and high recycling rate, and are widely used in beer and beverage packaging cans. After years of development, the manufacturing technology of aluminum cans has been continuously improved. Both the can lid and pull ring can be made of 5182 aluminum plate, greatly reducing the weight of aluminum cans and making them more convenient to use.

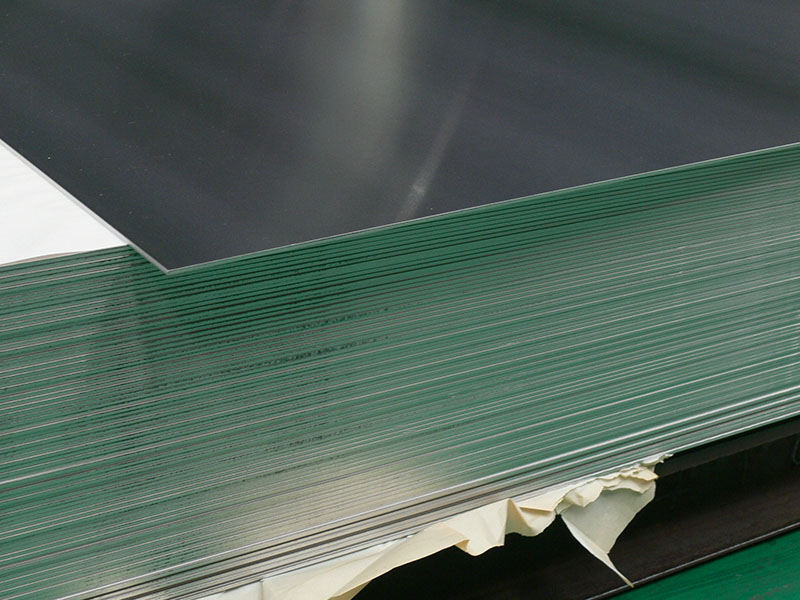

The 5182 aluminum plate used for aluminum alloy can lid and pull ring belongs to the Al Mg series anti rust aluminum, which has the characteristics of moderate strength, good corrosion resistance, and machinability. The surface smoothness is high, suitable for later processing such as slitting and slicing, and the stamping performance is excellent. Mingtai Aluminum's aluminum alloy can material can achieve flat plate shape, with excellent thickness control, small thickness tolerance, stable performance, ensuring later processing quality, and meeting customer needs.

Mechanical properties of 5182 aluminum alloy can lid pull ring

Tensile strength σ b (MPa): ≥ 175

Conditional yield strength σ 0.2 (MPa): ≥ 80

Elongation rate δ 5 (%): ≥ 15

According to user feedback, the performance of Mingtai Aluminum's 5182 aluminum plate meets the requirements for use

1. High flatness and good shape

Mingtai has advanced grinding equipment to ensure flat plate shape and strict thickness control, ensuring a thickness tolerance of ± 0.005mm.

2. Easy to process, stable performance

Mingtai selects raw materials and strictly controls each process to ensure that the product has appropriate strength and formability.

3. Recyclable, economical and environmentally friendly

The 5182 aluminum plate is made of Al Mg series anti rust aluminum, which can resist acid and alkali corrosion, is durable, recyclable, and environmentally friendly.

4. Advanced equipment

Equipment: We have over 30 production lines and nearly 100 large-scale processing equipment developed independently in Germany, South Korea, Italy, and other countries.

WhatsApp: wa.me/+86-17320140933

E-mail: sale06@mingtai-al.com